Need to test a sustainable material or validate a circular concept?

Our Prototyping Lab gives you fast, flexible access to testing, forming, and developing fibre-based materials under real-world conditions. Whether you are scaling up, validating properties, or exploring a new application, we help you move faster from lab to line. All with circularity, feasibility, and ESPR readiness in focus .

Prototyping Lab for

SUSTAINABLE Innovation.

What can you Do in Our Prototyping Lab?

From early concept to industrial pilot, we help you move fast, think sustainably, and stay credible. Through a unique mix of technical expertise and co-creative approaches, we support you every step of the way, from concept to scalable solution.

-

Experiment with new material blends and recipes using sustainable or side-stream residual inputs, customised to your needs.

-

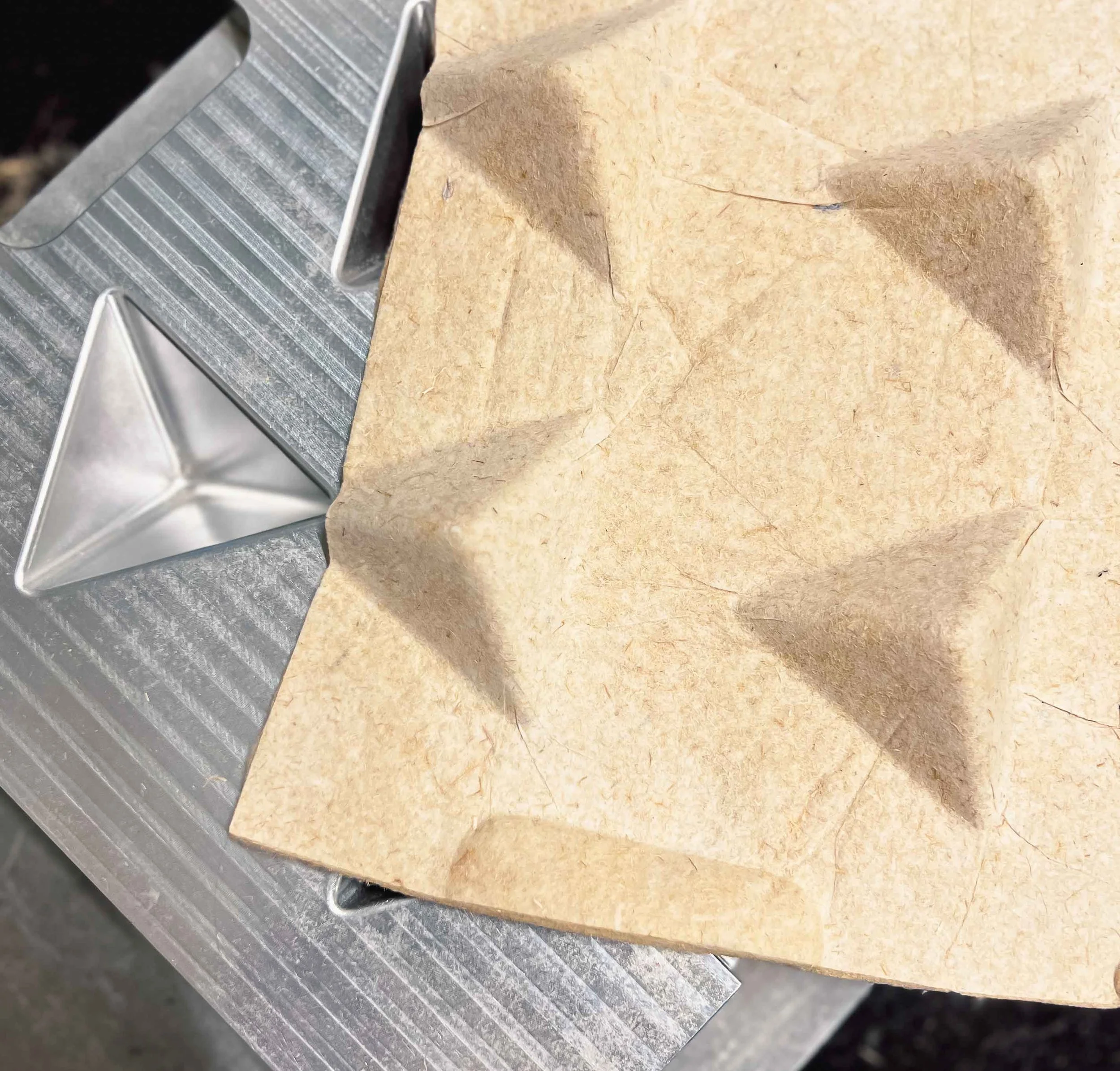

Shape prototypes through thermoforming or moulding to explore form, function, feel, and performance.

-

Check how your materials behave in real conditions, before scaling up or investing in tooling.

-

Simulate early-stage manufacturing to refine materials, processes, and product ideas.

-

Assess traceability, recyclability, and compliance to prepare your solution for scale-up and upcoming circular standards.

WHO is THE lab for?

Our prototyping lab is a hands-on environment where ideas move from concept to reality through iteration, experimentation, and collaboration.

Sustainability and innovation teams who need tangible results to guide decisions.

R&D and product developers who need to move fast from idea to physical prototype.

Producers and process owners who want to test material behaviour under production-like conditions.

Designers and material creators who want to shape sustainable materials into prototypes.

Industrial developers and engineers who are scaling up new processes and want to define how a future production line could look.

Services in our prototyping lab

Material technologies.

Material separation, fibre opening and shredding

Airlay carding, thermo-bonding, needle punch.

3D forming, heat and cold pressing.

ADVANCED technologies.

Laser cutting, die-cut and sheet cutting.

3D printing.

Material characterisation.

Tooling design.

Missing any equipment or technology? Don’t worry!

Our Prototyping Lab evolves with every project. We invest when it makes sense, and partner with trusted experts and labs to access the right technologies when needed. This way, we stay flexible and always aligned with the most relevant innovations in circular materials and sustainable production.

Are You ready to prototype?

Got a material you want to test or an idea you want to try?

Book a 30-minute intro meeting to see if our prototyping lab is the right fit for your challenge.

Share your needs, and we will explore the possibilities together.

Why PROTOTYPE WITH US?

Prototyping isn’t just about speed; it’s about learning fast, failing smart, and scaling with confidence.

-

Cut development time, test ideas early, and avoid costly mistakes before scaling up.

-

Access forming equipment designed for fibre-based and recycled materials, with support from experienced circular innovators.

-

Explore the potential of side-residual streams, blends, or bio-based materials, tailored to your process and goals.

-

Validate performance, production fit, and traceability, so you can move forward with evidence, not guesswork.

-

Use the lab to prepare for evolving requirements like ESPR, EPR, and circular design, from material choices and disassembly strategies to traceability and documentation.

Whether you are preparing for EPR, exploring design for disassembly, or validating a recycled fibre, we help you turn complexity into clarity and stay ready for what’s next.

Order samples To Discover

Nonwoven Innovation.

The world of fibres and nonwoven materials is limitless, offering endless possibilities for sustainable design and advanced performance. At The Loop Factory, we push boundaries with airlay technology and needlefelt processes, transforming fibres into solutions that shape a healthier planet.

Experience the potential firsthand—order your nonwoven material samples today and explore how texture, durability, and flexibility align with your vision.

JOIN OUR Newsletter.

Let us inspire and update you on how to turn unused resources into sustainable solutions.

We explore the endless potential of nonwoven technologies to create a healthier planet.