Scaling circular acoustic panels

This week, we met with our partners in the Ceilings4Life project and welcomed Inta Dūce, External Monitoring Expert from the LIFE Programme.

The purpose of the meeting was clear: to review progress and ensure that development is aligned with what we have committed to deliver.

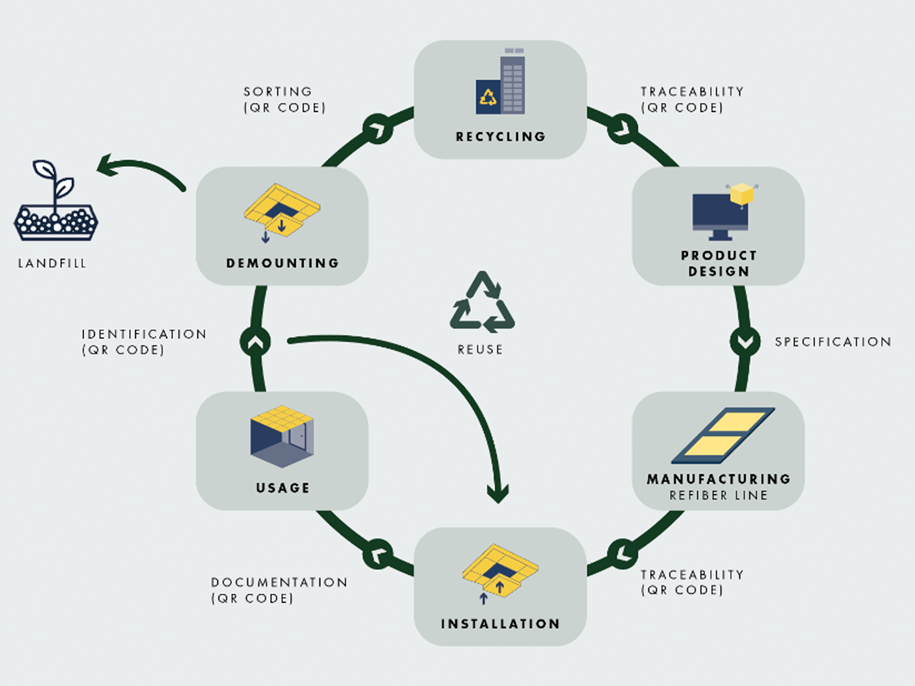

Within Ceilings4Life, we are developing and validating a manufacturing process that recycles glass wool waste into circular Refiber™ baseboards. The objective is clear: a solution that can move from pilot to stable industrial production and from baseboard to finished acoustic panel.

This is where many producers face challenges:

How do you introduce recycled raw materials without affecting product quality?

How do you adapt processes without disrupting production flow?

How do you secure compliance while driving innovation forward?

Ceilings4Life addresses these questions through structured development, technical validation and close collaboration across the value chain.

If you are working with production side streams and exploring how they could become part of a circular solution, we are happy to start that conversation.

Ceilings4Life is co-funded by the European Union under grant agreement No 101216180. Views and opinions expressed are however those of the author(s) only and do not necessarily reflect those of the European Union or CINEA. Neither the European Union nor the granting authority can be held responsible for them.