Prototyping Lab for

Circular Innovation.

Prototyping Lab - where sustainable ideas turn real. From fibre-based materials to circular products, we prototype, test, and scale solutions that reduce waste, support ESPR goals, and accelerate your circular transition.

What is a Prototyping Lab?

A prototyping lab is a hands-on environment where ideas are brought to life through iteration, experimentation, and development. Ours is designed specifically for sustainable innovation and the development of more sustainable fibre-based materials, technologies and processes:

Rapid material and product prototyping

Testing and verification of new technologies

Insights that accelerate circular transition

What You Can Do in Our Lab?

We support you from concept to pilot, combining technical capabilities with co-creative methods.

Develop & test circular fibre-based materials

Validate technologies, production methods and performance

Prototype functional products and components

Explore scale-up strategies and traceability

Why DO YOU NEED A LAB?

Prototyping isn’t just about speed; it’s about learning fast, failing smart, and scaling with confidence.

Cut development time and reduce uncertainty

Discover hidden potential in materials or side-streams

Avoid costly scale-up mistakes

Support ESPR and circularity goals with evidence

Whether you are preparing for EPR, exploring design for disassembly, or validating a recycled fibre, our lab brings clarity to complexity.

services IN OUR prototyping lab.

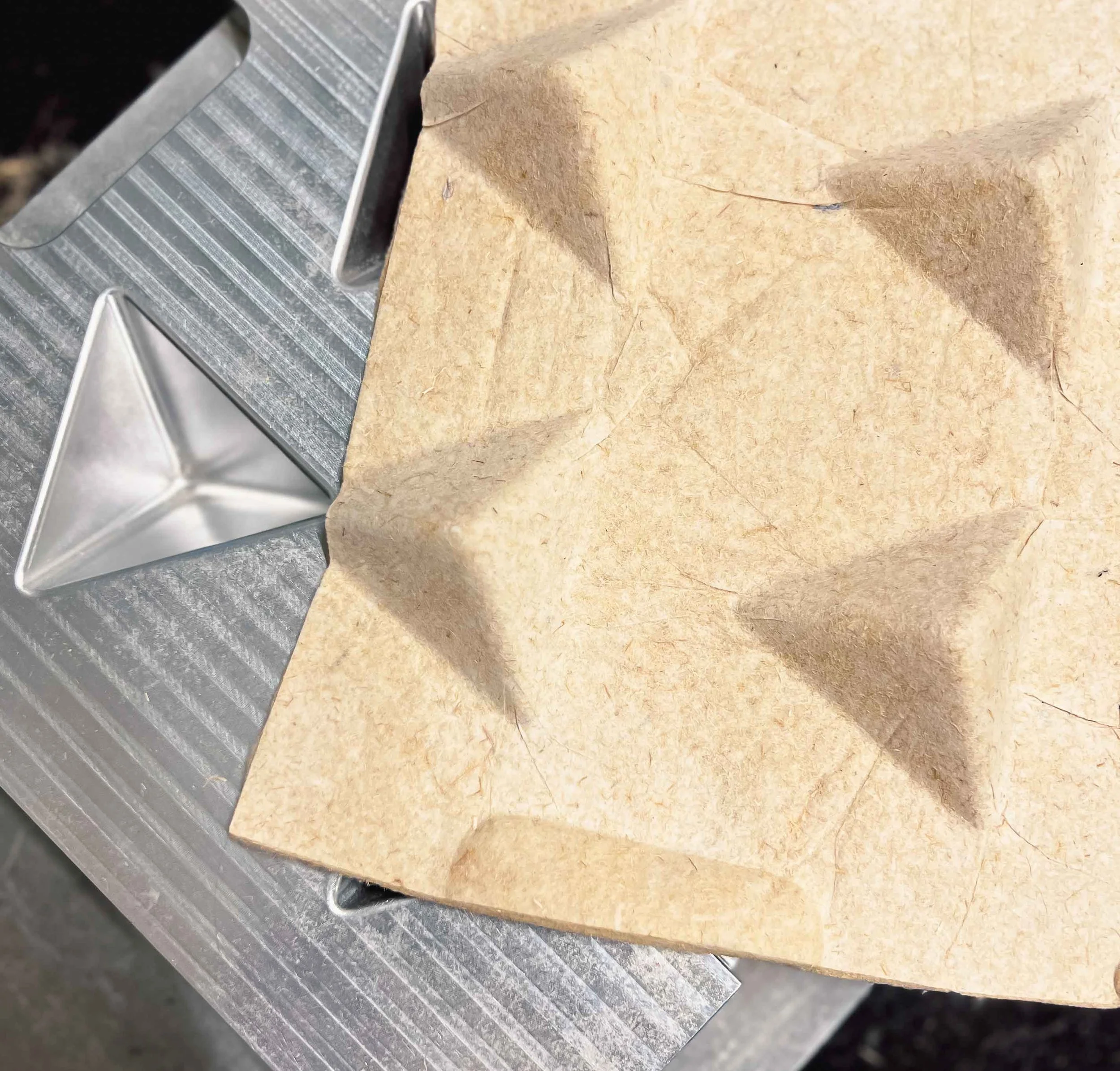

The Loop Lab's key processes are material transformation and mechanical recycling, focusing on nonwoven technologies. Our expertise is converting fibre-based materials into valuable resources that can be mechanically recycled into relevant products. These methods promote sustainability and support a circular economy by reducing waste and saving resources.

Material technologies.

Material separation, milling

Airlaid, carding, thermo-bonding, needle punch

3D forming, heat pressing

ADVANCED technologies.

Laser cutting, punching and sheet cutting

3D printing

Material characterisation

Tooling design

Missing any equipment or technology? Don’t worry!

With a wide range of partners supporting us, our lab grows with the projects, and we keep up the speed with the most interesting innovations.

Order samples To Discover

Nonwoven Innovation.

The world of fibres and nonwoven materials is limitless, offering endless possibilities for sustainable design and advanced performance. At The Loop Factory, we push boundaries with airlay technology and needlefelt processes, transforming fibres into solutions that shape a healthier planet.

Experience the potential firsthand—order your nonwoven material samples today and explore how texture, durability, and flexibility align with your vision.

JOIN OUR Newsletter.

Let us inspire and update you on how to turn unused resources into sustainable solutions.

We explore the endless potential of nonwoven technologies to create a healthier planet.